RECOMMENDED TOOLS

[9] Fywheel setting rod 0188- X

[16] Tool for fitting sealing ring (-).0188-AJ

[43] PR.0516.AO Balance shaft adjustment spacers

[44] Balance shaft positioning gauge (-).0190.D

[45] Balance shaft positioning gauge flange (-).0190.E

REMOVAL SERVICE POINTS

1.Remove The lower casing.

2.Remove the lower oil gauge guide.

3.Remove the upper oil sump.

4.Remove the front sealing panel (104).

5.Remove the oil pump (111) and its chain (108).

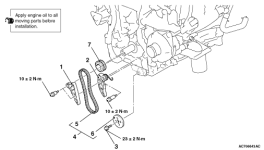

6.Remove the key (109).

7.Remove the gear wheel (110).

8.Remove the balancing shafts housing.

INSTALLATION SERVICE POINTS

1.Install the tool [9].

2.Install the adjustment 2 spacers [43].

3.Position the blind holes "n" of the balance shafts upwards.

4.Introduce the 5 mm diameter pins of the tool [44] into the blind holes "n".

5.Install the tool clamp [45] on the tool [44].

6.Gently tighten the screw of the tool [45].

7.Refit the balance shaft housing (25).

8.Engage the balance shaft housing (25) on its centring pins.

9.Remove the tool bearing cap positioning tool kit MB996219 [45], [44].

10.Remove the tool the engine flywheel peg [9].

11.Screw the 8 screws (26) in place.

12.Tighten the bolt (26) to temporary to torque of 10 N·m in the order shown.

13.Tighten the bolt (26) to angle of 60 ± 5° in the order shown.

14.Install the seal (27) (new).

15.Install the pinion (28).

16.Install the key (29).

17.Install the chain (32)

18.Install the oil pump (31)

19.Screw the screws (30) in place (respect the marks made at the time of removal).

20.Tighten the bolt (30) to temporary of hand.

21.Tighten the bolt (30) to torque of 16 ± 30 N·m

22.Put a bead of sealing paste (index E10) onto the sealing plate (104).

23.Install sealing plate (104)

24.Tighten the bolt (103) to torque of 14 ± 1 N·m

25.Install the sealing plate fitted with its fitting cone.

26.Position the sealing grommet (35); Using tool [16].

27.Remove tool [16].

28.Remove the fitting cone.

29.Apply a bead of sealing paste (index E10) to the upper oil sump.

30.Install the upper oil sump (37).

31.The 20 bolts (36) (respect the marks made at the time of removal).

32.The lower oil gauge guide (38).

33.The bolts (39).

34.Tighten the bolt (39) to 9 ± 1 N·m.

35.Bolt (36) tightening sequence:

36.Pre-tighten to 10 N·m (In the order shown).

37.Tightening torque 16 ± 3 N·m (In the order shown).

38.Install the lower oil sump (40).

39.Bolt (41) tightening sequence:

40.Pre-tightening to 10 N·m (In the order shown).

41.Tighten to 16 ± 3 N·m (In the order shown).

TORQUE SPECIFICATIONS

Item

Tightening torque

Alternator

Accessory mounting bracket bolts

20 ± 2 N·m

Alternator bolts

41 ± 4 N·m

Alternator rear support bolts

40 ± 4 N·m

Tensioner roller bolt

43 ± 6 N·m

Tensioner roller bolt

30 ± 3 N·m

Flywheel

Flywheel bolts

15 ± 1 N·m → 47 ± 4 N·m

Fuel injection pipe assembly

coolant outlet housing bolts

8 ± 1 N·m

High-pressure fuel pump bolt

22 ± 2 N·m

Diesel injector fixing clamp bolt

5 ± 1 N·m → 130° ± 5°

Hi-pressure fuel pipe / injectors bolt

22 ± 2 N·m → 25 ± 2 N·m

Hi-pressure fuel pipe clamp bolt

8 ± 2 N·m

High-pressure fuel injection commnrail

18 ± 2 N·m

Intake manifold

Oil cooler and filter assembly mounting nut

16 ± 3 N·m

Oil sediment bowl

8.5 ± 3 N·m

Intake manifold

9 ± 1 N·m

Turbocharger assembly

Turbocharger fixing bolt

25 ± 2 N·m

Turbocharger bracket bolt

30 ± 3 N·m

Turbocharger lubrication hollow bolt

27.5 ± 3 N·m

Exhaust gas recycling duct

10 ± 1 N·m

Exhaust gas recycling valve

10 ± 1 N·m

Cylinder head cover

Accessories drive pulley bolt

Pre-tighten to 70 ± 25 N·m, then carry out an angular tightening of 82 ± 3°

Cylinder head cover bolt

10 ± 1 N·m

Camshaft position sensor bolt

6 ± 1 N·m

Timing belt

Camshaft pulley screw bolt

20 ± 5 N·m → 60 ± 5°

Guide roller screw bolt

43 ± 4 N·m

Engine mounting bolt

60 ± 5 N·m

Engine mounting bolt

80 ± 5 N·m

Coolant pump fixing bolts

10 ± 1 N·m

Tensioner roller screw

25 ± 2 N·m

Drive pulley

70 ± 7 N·m

Cylinder head

Glow plugs

10 ± 1 N·m

Cylinder head bolt

Pre-tighten to 22 ± 2 N·m, then tighten to 60 ± 5 N·m

Un tighten by 1 turn

Tighten to 60 ± 5 N·m

Angular tightening of 220 ± 5°

Timing belt guide roller

Pre-tighten to 15 N·m, then tighten to 43 ± 4 N·m

Timing belt tensioner roller

250 ± 30 N·m

RH engine mounting

Pre-tighten the 4 screws to 10 N·m

Tighten the 8 diameter screw to 20 ± 2 N·m

Tighten the 10 diameter screws to 45 ± 2 N·m

Cylinder head

Cylinder head bolt

Pre-tighten to 22 ± 2 N·m, then tighten to 60 ± 5 N·m

Un tighten by 1 turn

Tighten to 60 ± 5 N·m

Angular tightening of 220 ± 5°

Camshaft bearing cover

Tighten the studs to 10 ± 1 N·m

Pre-tighten the 28 6 diameter screws to 5 N·m

Tighten the 28 6 diameter screws to 10 ± 1 N·m

Timing chain tensioner bolt

7 ± 1 N·m

Camshaft bearing cap bolt

10 ± 1 N·m

Oil pan and oil pump

Balance shaft housing bolt

10 N·m → 60 ± 5°

Oil pump bolts

16 ± 3 N·m

Sealing plate bolt

14 ± 1 N·m

Lower oil gauge guide bolts

9 ± 1 N·m

Upper oil sump bolts

10 N·m → 16 ± 3 N·m

Piston and connecting rod

Piston base jet bolts

10 ± 1 N·m

Crankshaft bearing cap bolts

25 ± 2 N·m → 60 ± 5°

Con-rod screw bolts

20 ± 2 N·m → 48 ± 5°